Mixing

Mix resin for 1 minute before adding hardener. Add hardener to resin pail and mix thoroughly for 4 to 5 minutes. For less than full kit mixing, a 2:1 by volume (3.1:1 by weight) mix ratio must be used. Always use hand and eye protection when working with or near epoxies.

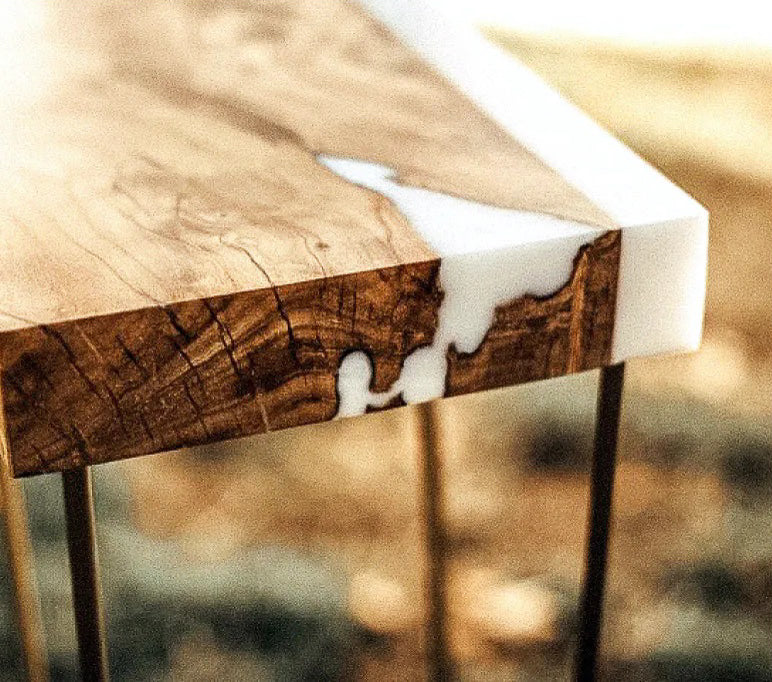

Application

Working area should be clean, dry, and free of dust. SnowWhite can be poured at 13-38mm (0.5-1.5”) per layer. SnowWhite will not shrink while curing under normal conditions. However, it may slowly fill cracks and voids in live edge wood pieces, causing the resin level to drop. Be prepared to add more epoxy as needed.

Epoxy releases heat when curing. For pours of 16L or more, multiple thinner pours may be necessary to prevent overheating. Fans blowing across the curing epoxy may also be used to help dissipate heat. For best adhesion between layers, wait until the first layer is tacky to touch before pouring a second layer. If the previous layer is no longer tacky, sand with 220 grit sandpaper and wipe down before pouring another layer.