FlowCast® SPR

The Premium Casting Epoxy for Small Projects

Perfect for Small Pours

¼" to 1" Thick per Layer

Faster Curing

Finish Your Projects in a Weekend

Bubble-Free Castings

Excellent Air Release

Outstanding Transparency

Cures Water Clear

The Premium Casting Epoxy for Small Projects

Perfect for Small Pours

¼" to 1" Thick per Layer

Faster Curing

Finish Your Projects in a Weekend

Bubble-Free Castings

Excellent Air Release

Outstanding Transparency

Cures Water Clear

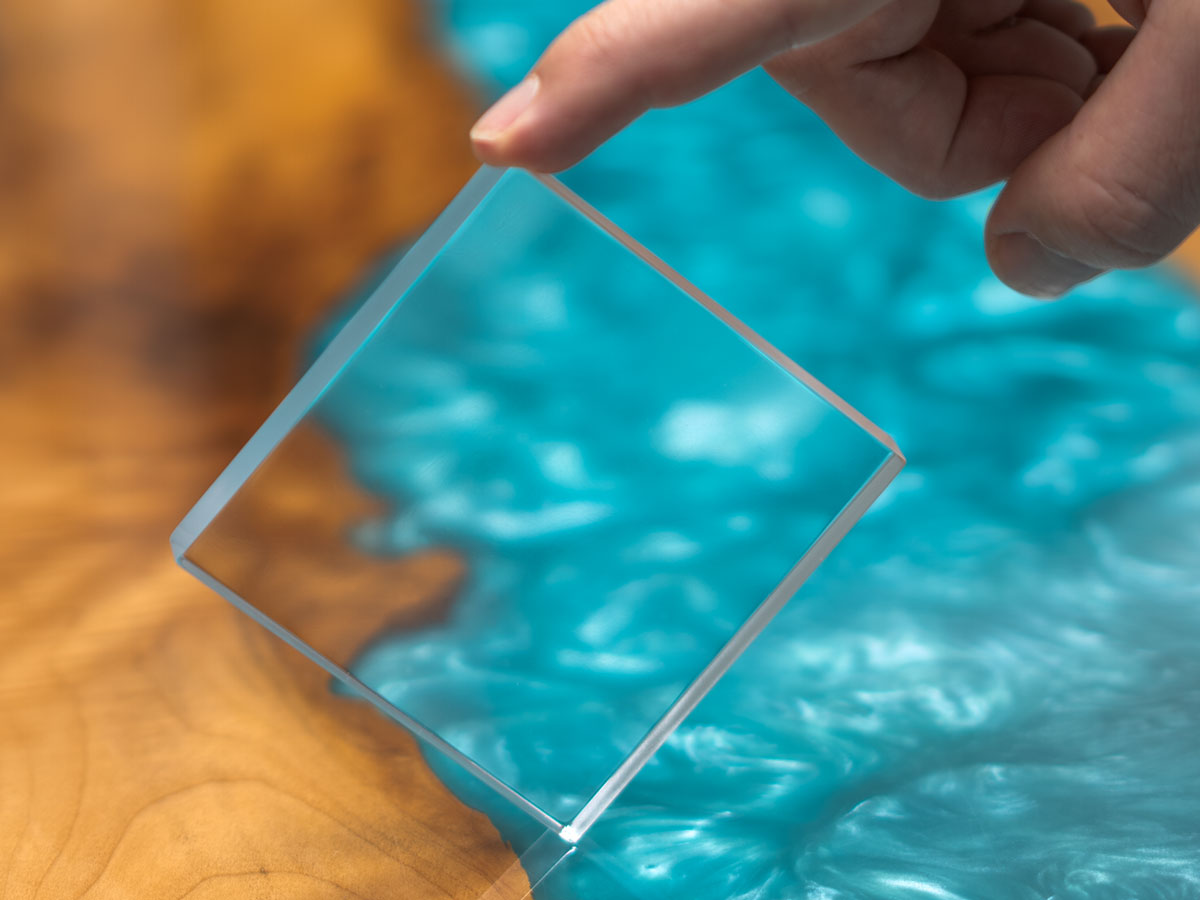

FlowCast SPR is a high-quality fast curing casting epoxy formulated with a simple 2:1 mix ratio. This small-pour casting resin is ideal for woodworking projects with thinner profiles, such as coasters and serving trays. It can also be tinted with EcoPoxy liquid or metallic pigments to create custom colors and artistic effects.

FlowCast SPR is designed for pours from 6-25 mm (¼-1") per layer, with a maximum volume of 3 L. FlowCast SPR can be worked using the same tools you have in your woodshop, making it a trusted woodworking epoxy for makers and hobbyists.

FlowCast SPR can also be used as a clear, strong wood filler in small voids or surface imperfections, allowing users to achieve smooth, professional finishes on live-edge or decorative pieces.

With EcoPoxy’s growing line of pigments and accessories, you’ll find everything needed to bring your epoxy projects to life.

Used to Create:

| Pour Depth | 6-25mm (0.25-1") for pours up to 3 L |

| Mix Ratio by Volume (A:B) | 2:1 |

| Mix Ratio by Mass (A:B) | 2.5:1 |

| Working Time (in mold) | 4 - 5 Hours* |

| Set To Touch | 24 hours |

| Demolding Time | 24 Hours |

| Time Finishing | 1 day for 25mm (1”) pour* |

| Full Cure | 3 Days* |

| Working Temperature | Resin, workpiece, and workspace temperatures should be 20-25°C (68-77°F) |

| Storage Temperature | 15-25°C (59-77°F) |

| Clean Up | Isopropyl/Denatured Alcohol or Warm Soapy Water |

| Shelf Life | Two years in unopened container, 3 months once opened |

*Times based on 25mm (1”) deep casting at a volume of 1.7L. Individual project times may vary depending on pour depth, volume, ambient temperature, and humidity.

FlowCast SPR provides the same beautiful results as FlowCast with two key differences:

Yes, FlowCast SPR is suitable for multi-layer pours. Additional layers should be poured when the previous layer has reached set to touch. To prepare the epoxy surface for the next pour, scuff the surface with 220 grit sandpaper. Remove excess dust and debris, then wipe clean with denatured or isopropyl alcohol. You can then pour the next layer.

If you are planning to pour deeper than 25 mm (1”) and at a volume greater than 3 L, pouring in multiple layers is suggested to prevent overheating. In large quantities, FlowCast SPR can generate significant heat, which can cause projects to yellow or form cracks. If multiple pours of FlowCast SPR is not an option, for projects that require pours greater than 25 mm (1”) in depth, it is recommended to use FlowCast.

We recommend seal coating any surfaces that will be submerged in FlowCast SPR. Seal coats help prevent air and moisture migrating out of submerged materials, which can cause bubbles. UVPoxy is the preferred system for seal coats as it is a faster curing resin made for applying in thin layers. FlowCast SPR can also be used but will not get to the tacky state as quickly. Cured seal coats should be abraded and cleaned before proceeding with pours.

All epoxies yellow over time. To combat this, we formulated FlowCast SPR with UV stabilizers. These additives absorb UV light and prevent damage to the resin. Eventually, the stabilizers will lose their effectiveness. Adding metallic or liquid pigments to FlowCast SPR will help it resist yellowing better than if it is left transparent. Completed projects should not be kept outdoors.

Shake Part B well before use. In a clean, dry container combine (by volume) 2 parts resin with 1 part hardener and mix thoroughly for 4-5 minutes. Add Liquid or Metallic pigments as desired and mix until evenly dispersed.

Working area should be clean, dry, and free of dust. FlowCast SPR can be poured at 6-25 mm (¼-1”) per layer. FlowCast SPR will not shrink while curing under normal conditions. However, it may slowly fill cracks and voids in live edge wood pieces, causing the resin level to drop. Be prepared to add more epoxy as needed.

Epoxy releases heat when curing. For pours deeper than 25 mm (1") and/or at a volume greater than 3 L, multiple thinner pours may be necessary to prevent overheating. For best adhesion between layers, wait until the first layer is fully set to touch. Sand with 220 grit sandpaper and wipe down before pouring another layer.

Visit our Tutorials section for articles & videos on best ways to use our products.

EcoPoxy TutorialsCategory: Pigments

Create an Unlimited Array of Custom Effects

Our Metallic Color Pigments are composed of fine mica nanoparticles coated with pigments that create iridescent and multi-dimensional effects. When...

View full detailsCategory: Pigments

Rich & Vibrant Colors to Make your Project Unique

Our Liquid Color Pigments are specially formulated to mix thoroughly and stay suspended in our casting and coating epoxies. One drop of these highl...

View full detailsCategory: Accessories

Mix with Confidence

EcoPoxy Graduated Mixing Cups have been designed with our users in mind and are customized for woodworkers and artists. They include easy-to-read s...

View full details

FlowCast SPR is designed for ¼" to 1" thick layers in pour volumes up to 3 L. This makes it the ideal casting resin for small-scale live edge wood projects.

As a fast-curing casting epoxy, FlowCast SPR helps you complete projects faster. Under recommended conditions and when applied according to the Application Guide, most pours are ready for finishing within a day, perfect for weekend builds and rapid turnaround.

The low viscosity of FlowCast SPR provides excellent air release, allowing trapped air to rise and escape. This significantly reduces bubbles and results in clear, smooth, high-quality castings.

FlowCast SPR cures water-clear for a clean, glass-like finish. It also blends beautifully with EcoPoxy liquid and metallic pigments, enabling custom colors, gradients, and visual effects.

Looking to purchase EcoPoxy for your next project? You can find EcoPoxy products at one of our many retailers worldwide.